Dimensional Metrology

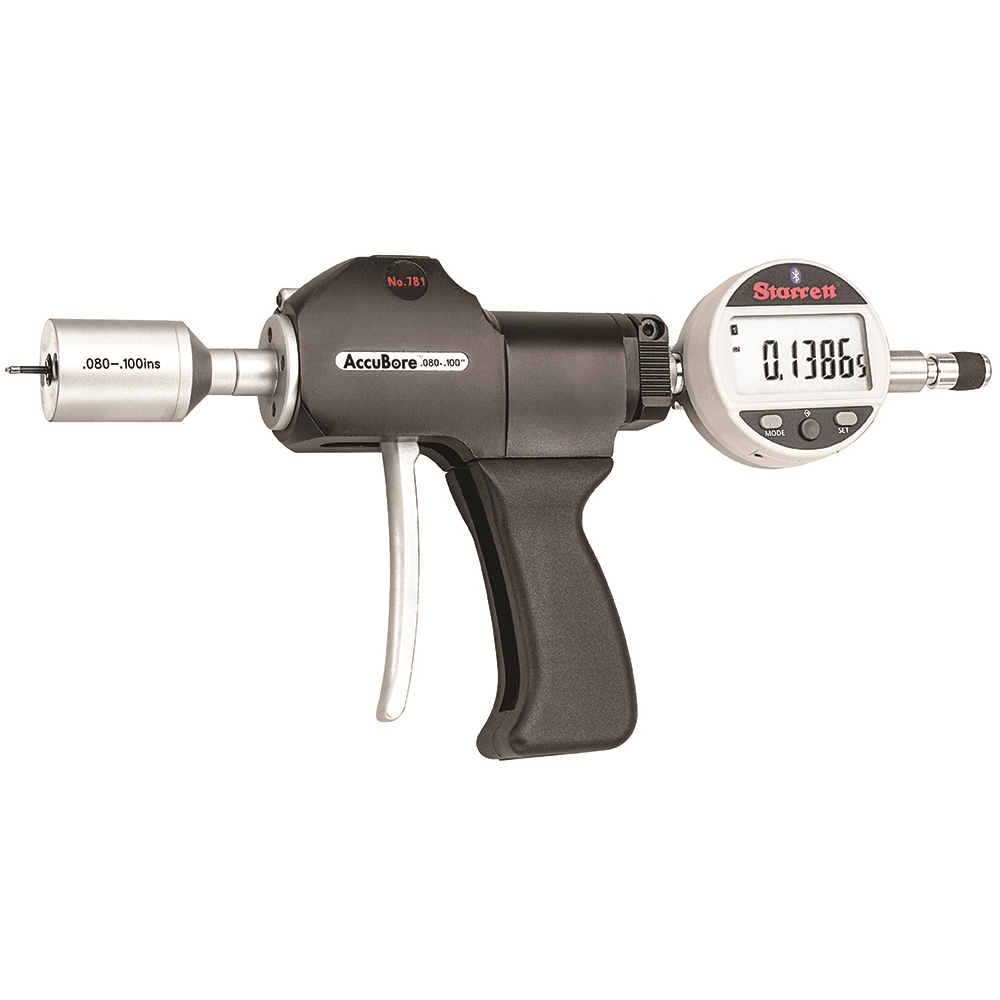

Bore Gages

A bore gage measures inside hole diameter with high accuracy. The controller can either turn a knob or release a trigger to extend pieces outward until the wall perimeter is touched by each contact. A bore gage is usually chosen by categorizing its precision measurement range, depth, accuracy requirements, and the number of contacts. A bore gage can have interchangeable measuring heads, different diameters, and extensions for depth, depending on their usage. A bore gage can also have electronic displays, micrometer-type vernier scales, or a dial that is similar to an indicator.

Calipers

Calipers provide a large measurement range, flexibility and accuracy up to 0.001.” These tools typically measure outside, inside, depth, and step dimensions. Available in digital, dial, and vernier versions.

Depth Gages

A depth gage can vary in form, complexity, cost and accuracy. The most accurate depth gages are a depth micrometer and a dial indicator depth gage. Less complex and precision measurement tools, such as rule gages and combination rule gages, are also available.

Digital / Dial Indicators

A digital or dial indicator is a precision measurement gage that shows movement visually, typically in very tiny increments. These are often used on fixtures that require repetitive inspection or adjustments on a machine. OCS Technologies offers a variety of each of the major classes: mechanical dial, electronic display, lever style test and back plunger. Each type has its own unique strengths. Electronic indicators can output data, while analog dial indicators are easy to read and understand for anyone. Resolution varies from 0.001″ to 0.00005″.

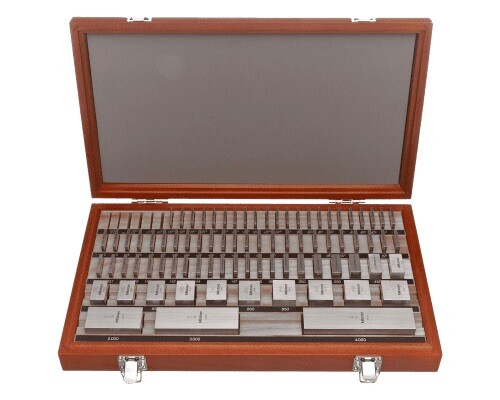

Gage Blocks

These metal blocks are used to calibrate machinery and equipment to any precision measurement of various sizes and for different purposes.

GO/NO GO Gages

A Go/No Go gage is a tool used to check if an item is within tolerance. Available as a plug gage, pin gage, or snap gage.

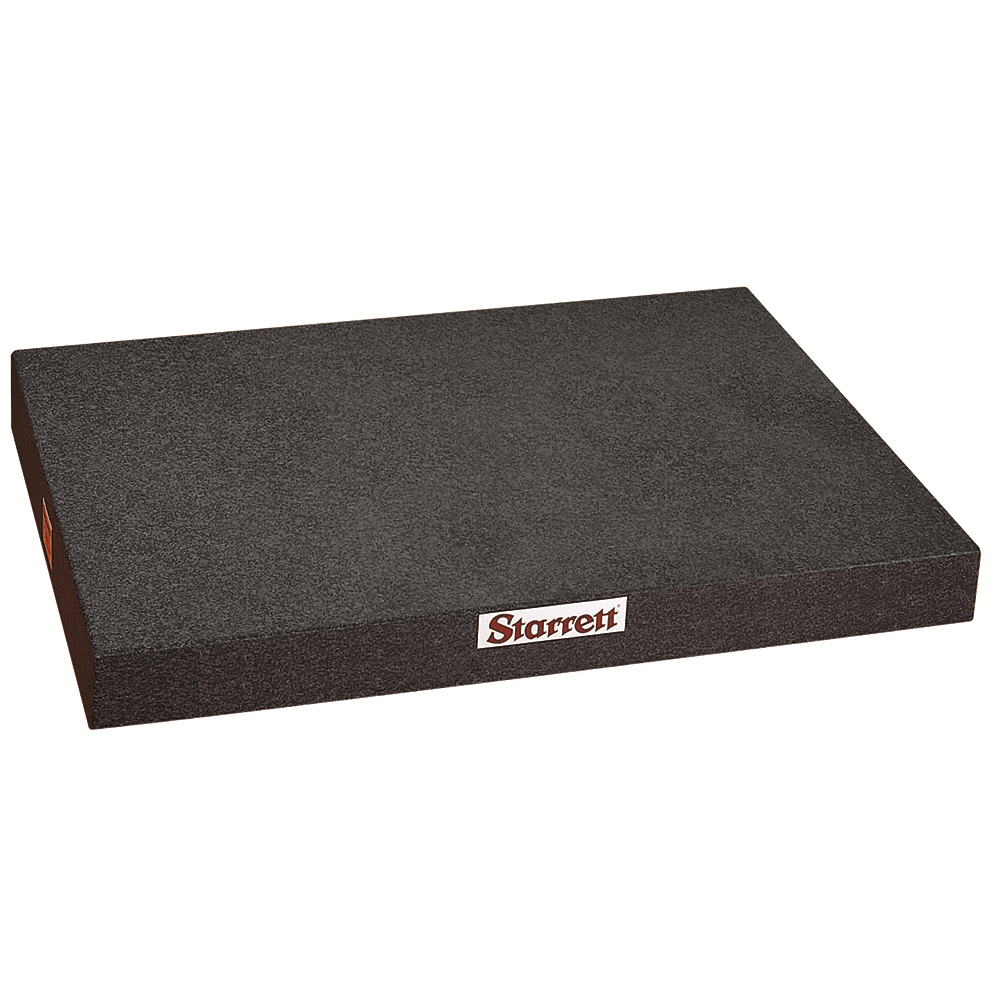

Height Gages

Used from a flat surface such as a granite surface plate, height gages provide precision measurement of the distance from the reference surface to some feature of a part, and can do so with exceptional accuracy. OCS Technologies offers a full range of height gages including electronic, dial, and vernier options. These tools are typically used in combination with the various scribes, attachments and accessories to complete the inspection work.

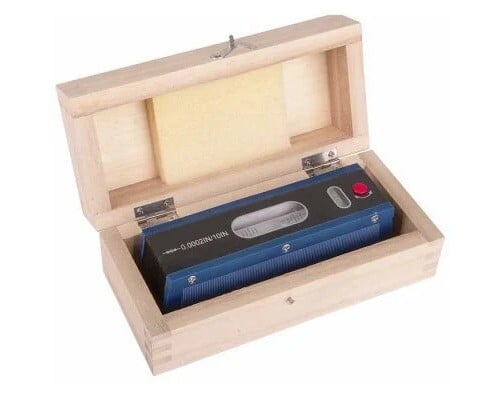

Levels

Precise machinist levels provide greater accuracy than common construction levels one might find at home. A precise machinist level must be used when the reference plane varies within the range of the level’s sensitivity.

Micrometers

A micrometer can come in a variety of types, including outside, inside, depth, bench, and heads. Precise measurement readouts are available in varying sizes with accessories and can be read as electronic, digital, and traditional vernier.

Optical Comparators

Optical comparators offer durable and affordable solutions for non-contact 2D precision measurement. At the center of these systems are the precision optics, along with fine lighting and a highly precise workstage. They combine to ensure bright, sharp images and exceptional accuracy. With a vast selection of styles, sizes, stages, lenses and other accessories, OCS Technologies has a comparator for most any precision measurement application.

DRO (Digital Read Outs)

OCS Technologies offers upgrade and retrofit Digital Read Outs (DRO) for existing optical comparators. This ensures you have the most up to date precision measurement capabilities without investing in a complete replacement.

Pin Gages / Pin Sets

Pin Gages / Pin Sets are tools used to check if an item is within tolerance. Available as a single gage or in sets.

Ring Gages

Ring gages are tools used to check external diameters as well as a calibration artifact for precision measurement.

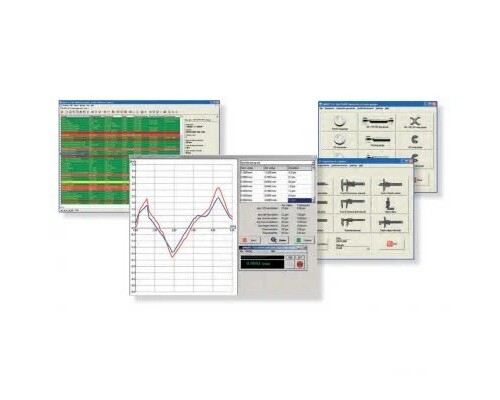

Software / Data Collection

Data collection is an increasingly important part of manufacturing, and one of the main drivers in the movement toward electronic precision measurement tools with output. This allows for real-time collection and recording of precision measurement data. transmission. From measurement to input, it reduces steps, saves time and can totally eliminate error in the data collection process.

Surface Roughness

Surface Roughness Testers measure the micro-irregularities, or roughness, of a given material or surface.

Explore Calibration & Repair Services

When your equipment needs calibration or repairs, OCS is here to help. Our factory-trained technicians provide expert service to restore precision, ensure compliance, and minimize downtime so you can keep moving forward.